Owensboro Grain Company (USA)

Combined heat and power facility helps grain processing company significantly reduce its dependence on utility power, slash power costs.

Background

Owensboro Grain Company produces a vast array of bio-based products from soybeans at its western Kentucky plants. The company aims to produce the highest quality products possible under the most favorable ecologically and environmentally sound conditions and minimize waste. To reduce its dependence on utility power and combat rising electricity prices in the region, the company began investigating combined heat and power (CHP) systems that could run on lower priced natural gas.

Solution

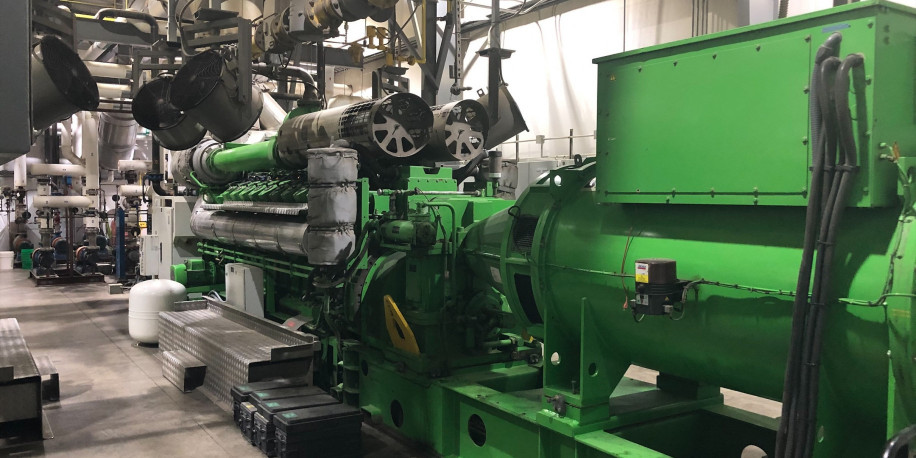

In January 2014, Owensboro Grain commissioned a cogeneration facility based on three Jenbacher* J620 reciprocating gas engines in a N+1 arrangement. Powered by natural gas, the CHP solution delivers 6.6 MW of power while gas engine exhaust waste heat is used to meet the plant’s process hot water needs. An oxidation catalyst installed at the engine exhaust effectively reduces CO emissions.

Results

Monitored, operated, and maintained by the company’s personnel, the CHP system operates 24/7, providing an independent electricity source to cover the facility’s operational needs. The company reports that the reliable system has delivered significantly reduced power costs as well as environmental benefits from lower greenhouse gas emissions.

Customer advantages

- Cost saving. Cogeneration systems usually save users about 40% when compared to separate power and heat generation. Owensboro Grain has reported significant saving in annual energy costs.

- Efficient. Owensboro Grain’s CHP system uses waste heat created during an engine’s operation to generate overall efficiencies as high as 80%, depending on the amount of recovered thermal energy used.

- Compliant. Annual stack testing is required to assure compliance with emission limits and the company reports significantly reduced GHG emissions with the CHP plant.

Location

Owensboro, USA

Installed engines

3 x J620

Electrical output

9.9 MW

Energy source

Pipeline gas

Commissioned

2014