OTHER ENGINE TYPES

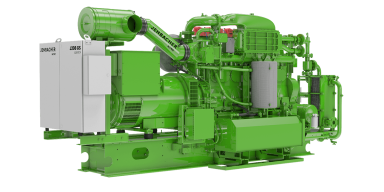

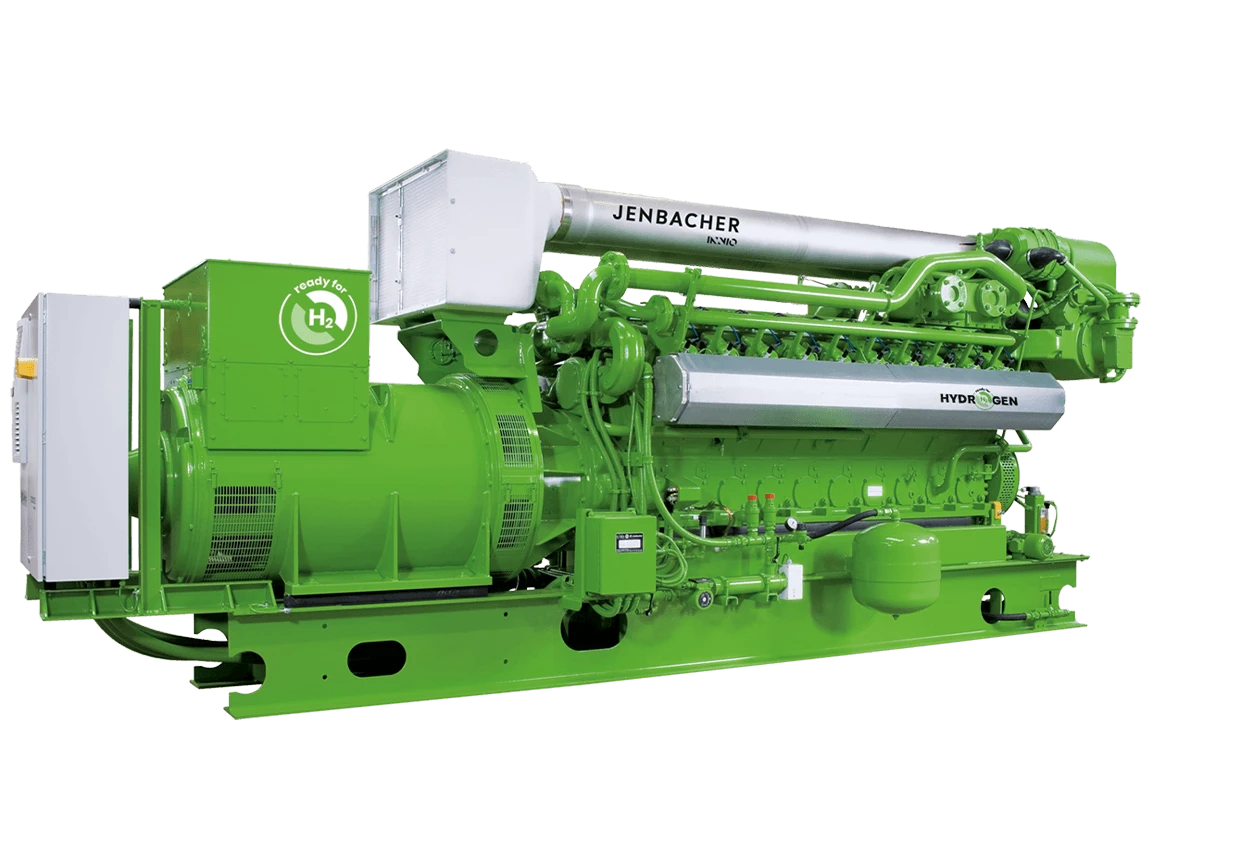

Jenbacher J320

The reference for robustness and reliability – now with higher efficiency!

Based on our proven Type 3 platform established in 1988 and continuously developed ever since, the next generation Jenbacher Type 3F engine offers proven robustness and reliability while delivering more efficiency than ever.

Jenbacher Type 3 proven – reliable – flexible ~11,000 Type 3 engines were delivered since 1988.

Change the scope of supply by clicking on a thumbnail.

Scope of supply:

* Provided technical data is for information only. Data ranges are calculated considering various gas quality levels and ambient conditions (standard or hot/tropical conditions, etc.).

Jenbacher can change the technical data unilaterally. In the case of such change, we will update the data on our pages as soon as we can.

Please reach out to our experts to get help with engines selection, obtain the technical parameters for your gas composition.

Output and efficiency at generator terminals. Energy input is according to DIN ISO 3046 and DIN 6271, respectively, with a tolerance of + 5%.

All data according to full load and subject to technical development and modification.

Based on emission values of 250 and 500 mg/Nm3 NOx at 5% O2 at dry exhaust gas.

Base for biogas and sewage gas versions: 65% CH4 / 35% CO2.

Base for landfill gas version: 55% CH4 / 40% CO2 / Rest N2.

L: 6,000 x W: 1,800 x H: 2,300 mm

L: 6,000 x W: 2,200 x H: 2,300 mm

L: 12,200 x W: 2,500 x H: 2,600 - 5,300 mm

Highlights of Jenbacher Type 3F engines

Building on its proven heritage, the new Type 3F 50 Hz engine now leads the way with next-generation technology innovation that delivers an up to 2 percentage point efficiency boost compared to earlier engine versions—up to 1,065 kWe—without sacrificing its proven reliability or robustness.

In addition to delivering efficiency as high as 43.2% when operating on pipeline gas, the Type 3F engine is optimized for reduced total hydrocarbon (THC) emissions, future-proof fuel flexibility, and enhanced serviceability.

Moreover, the latest 3F technology is retrofittable for the most of the installed Type 3 fleet.

To use Youtube, please give your consent to the creation of cookies used by this service.

Innovative design features

New cylinder head (4V)

Optimized for better gas exchange and improved cooling, the new cylinder head also delivers reduced THC emissions, improved combustion, and more robust valve and valve seat materials.

New power unit

Our new aluminum piston design helps minimize crevice volume for reduced THC emissions, improved combustion, and reduced oil consumption. Other key aspects of the design include a new piston bowl shape, liner, and scraper ring.

New knock control & ignition system

This enhanced system delivers better engine protection, more efficient combustion, and easier serviceability.

New valve train (4V)

A new valve train with a floating bridge makes service easier.

New camshaft

Our new camshaft gives you increased charge efficiency and enhanced Miller timing. Plus, your THC emissions are reduced, and you get better gas exchange.

Scope of supply:

Scope of supply, dedicated for applications, which require power generation only. If you are looking for simultaneous power and heat generation, please consider Combined Heat and Power Module (CHP Module) scope of supply.

Minimum scope of supply for genset:

- Engine and alternator installed on the frame

- Control panel

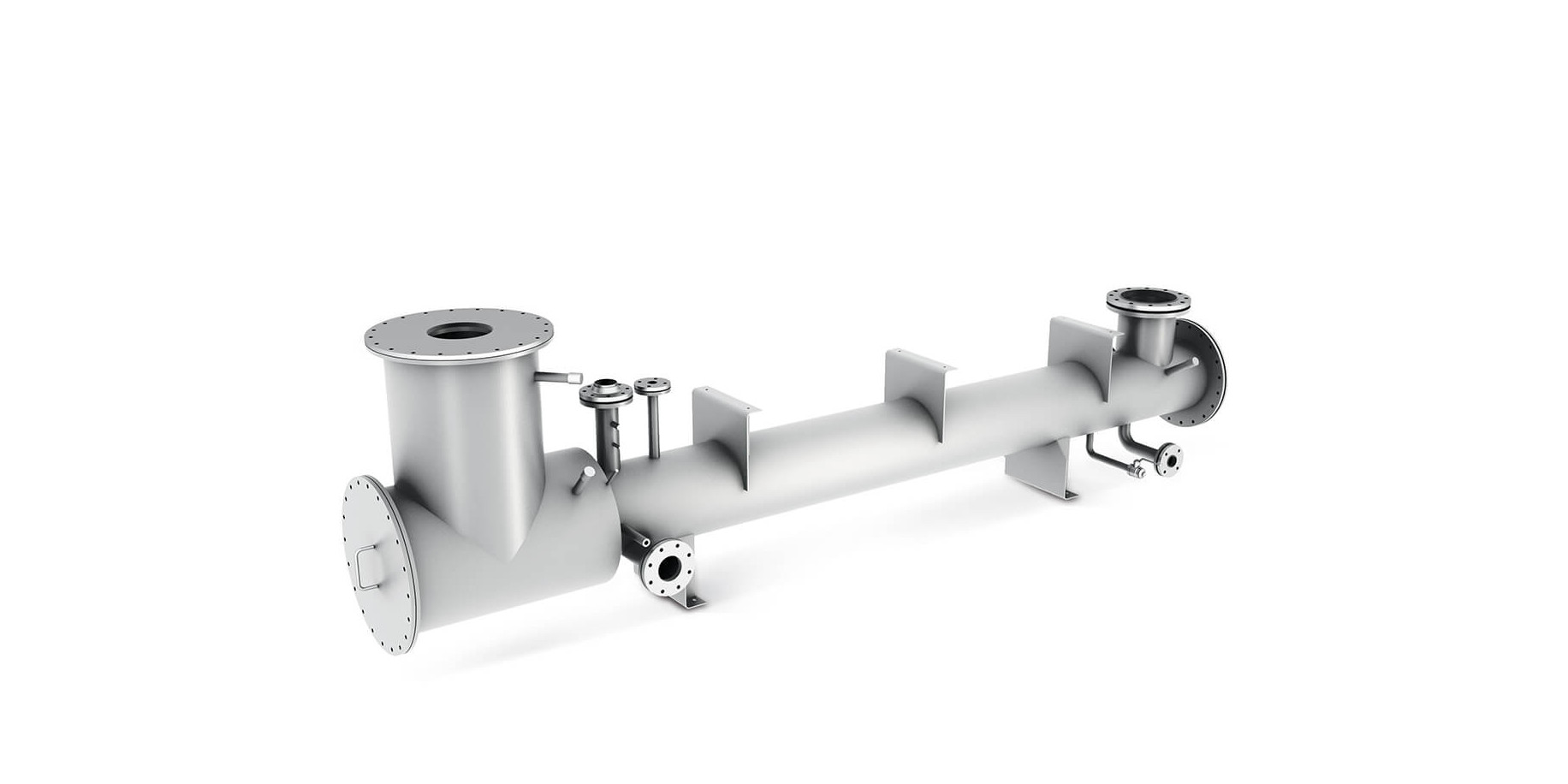

- Gas train

The scope of supply can be extended further with various balance of plant options (BOP), reach out to our specialists for help in selecting scope of supply and BOP options to fulfill your project’s needs.

Gensets can be installed inside a building or inside a container. To see more details about our containerized solutions, click here.

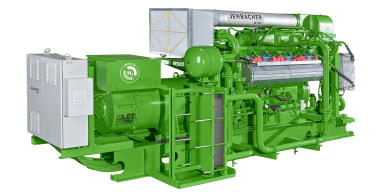

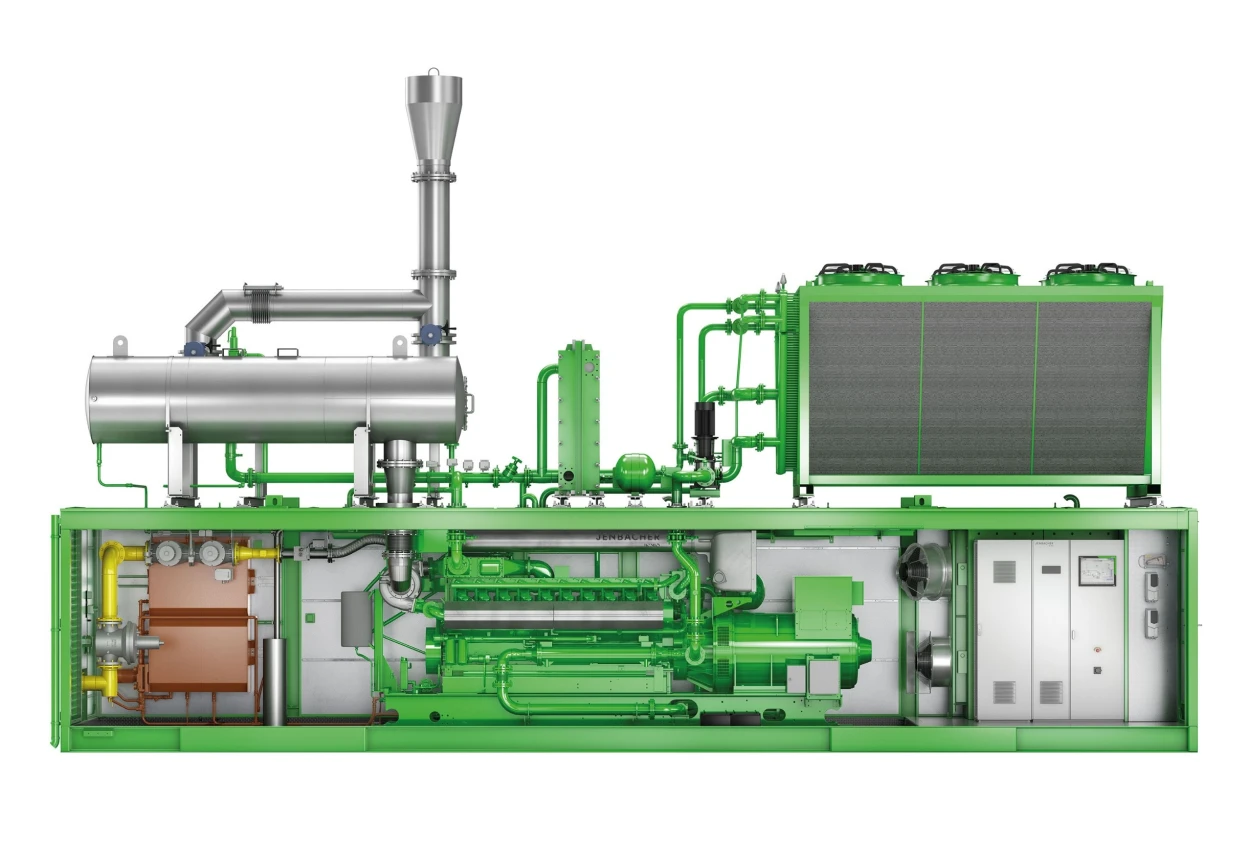

Combined Heat and Power Module (CHP Module) solutions allow customers to generate power and heat simultaneously at a very high total efficiencies, reaching 90% and even more.

Usual scope of supply:

- Engine and alternator installed on the frame

- Control panel, gas train

- Heat exchangers including exhaust gas heat exchanger

CHP Modules can generate hot water or steam at various parameters and can be integrated with your existing heat infrastructure. You can select the option that fits your project’s needs among the various heat recovery schemes provided by Jenbacher.

The scope of supply can be extended further with various balance of plant options (BOP), reach out to our specialists for help in selecting scope of supply and BOP options to fulfill your project’s needs.

CHP Modules can be installed inside a building or inside a container. To see more details about Jenbacher’s containerized solutions, click here.

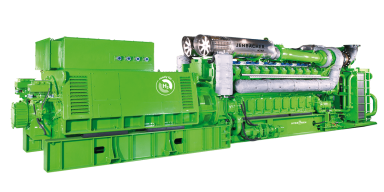

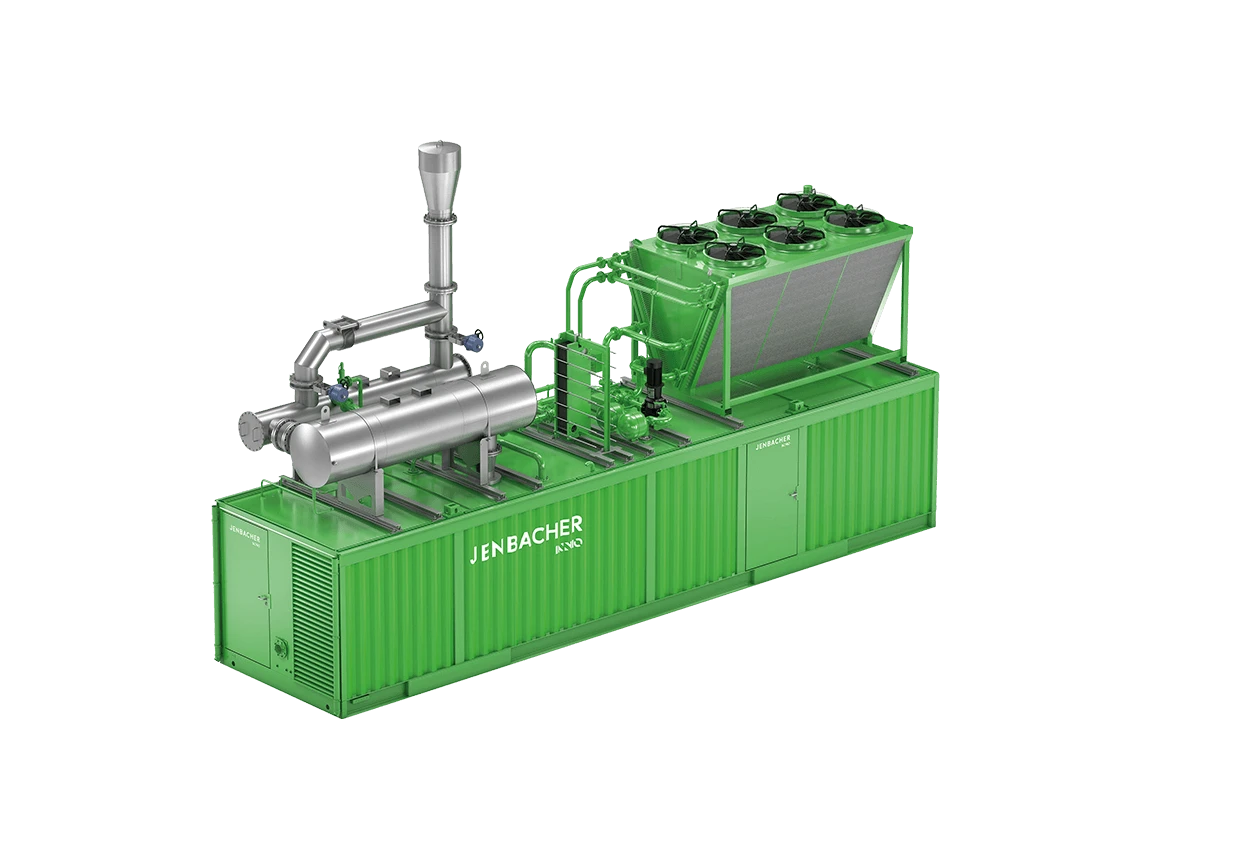

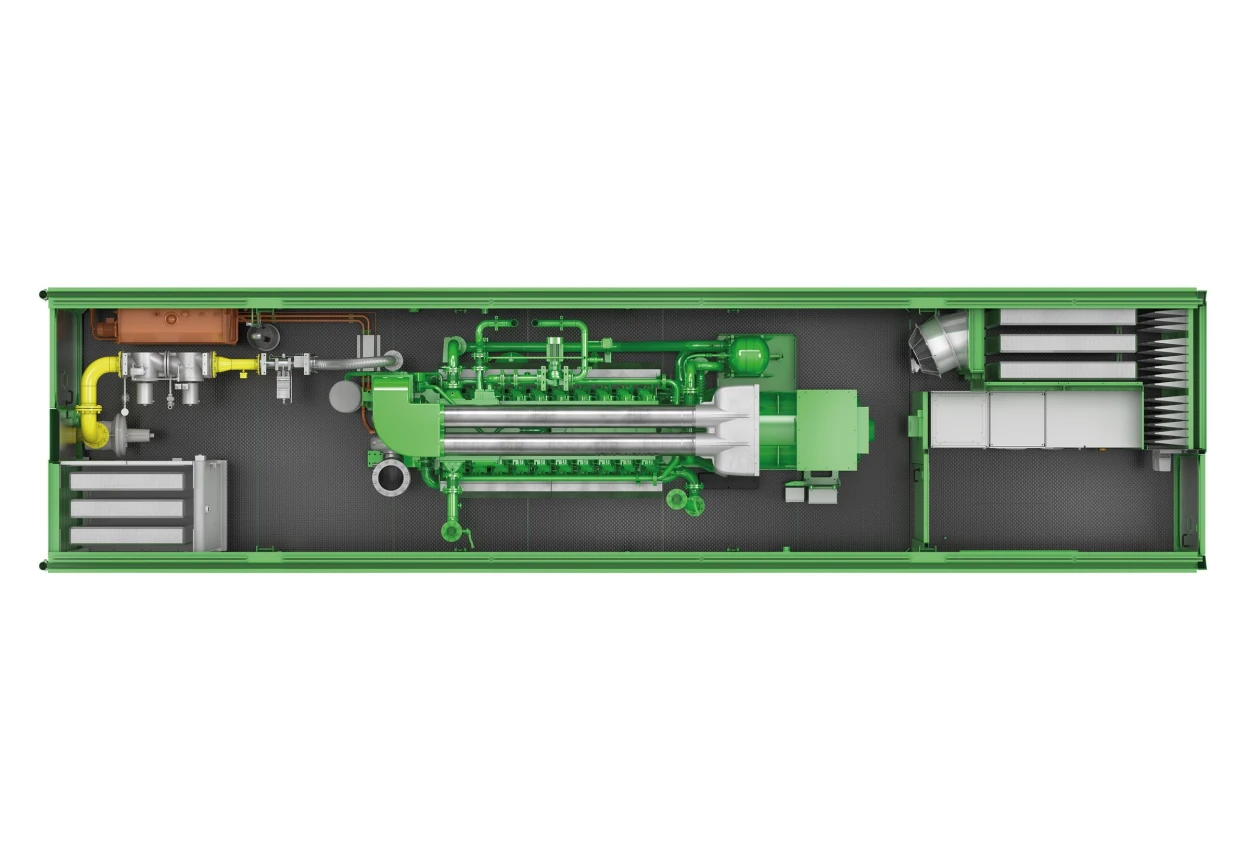

Jenbacher’s containerized solutions are “ready-to-use” power plants, allowing customers to minimize commissioning time. Jenbacher has produced containerized power plant solutions for decades, providing customers state of the art power generation technologies wrapped in well-designed, reliable packages.

Both genset and CHP module solutions can be supplied as containerized versions depending on your needs.

Usual scope of supply:

- Engine and alternator installed on the frame

- Control panel, gas train

- Container with integrated ventilation system

- Cooling systems

- Lube oil supply system

- Exhaust gas heat exchanger (for CHP module)

The scope of supply can be extended further with various balance of plant options (BOP), reach out to our specialists for help in selecting scope of supply and BOP options to fulfill your project’s needs.

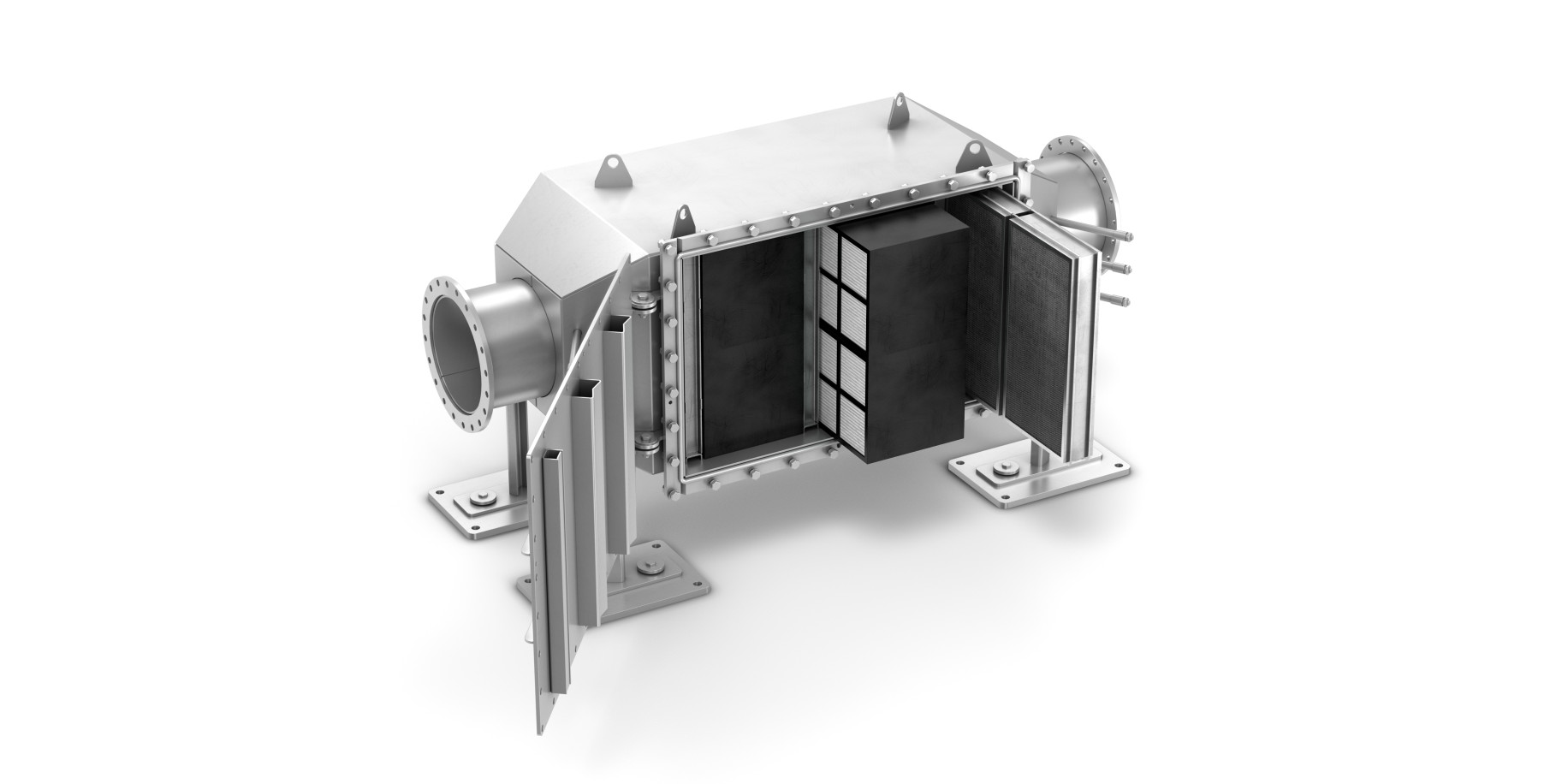

Balance of Plant (BOP)

The right auxiliary equipment is of critical importance in ensuring that a power solution is economically feasible and provides your business with reliability, availability, and efficiency. Click on the provided BOP options to learn more.

Reach out to our experts to select the configuration that fits your business’ needs.

Available BOP elements may vary, depending on the engine and application type.

Efficiency boost up to 43.2%

Reduced THC emissions

Future-proof fuel flexibility

Enhanced serviceability

Retrofittable for most of the installed fleet

Greater efficiency

Up to 2 percentage points improved fuel usage means savings for you

Lower THC emissions

Lower THC emissions lead to a smaller environmental footprint

Reduced oil cost

Less consumption and longer lube oil lifetime lower your oil life-cycle costs

Convenient upgrade

For your installed engines, applied anytime—ideally during your minor or major overhaul—for the latest technology

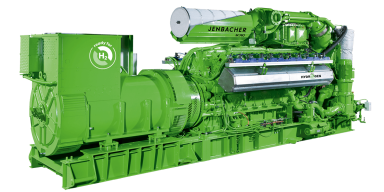

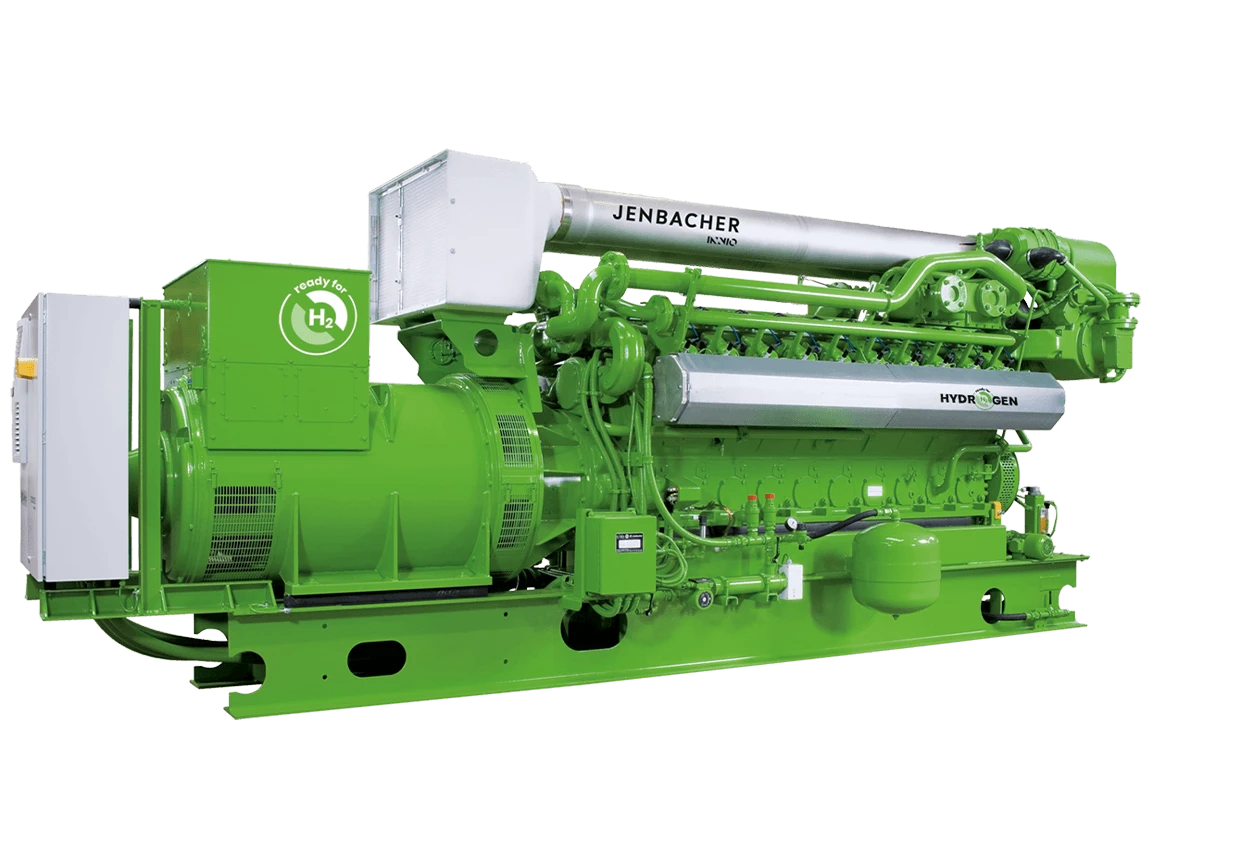

Future-proof fuel flexibility

The “Ready for Hydrogen” 1 option facilitates your move from conventional fuels today to (H2) operation tomorrow, once (H2) becomes more readily available

1 – Optional scope on demand

Watch the video on available 3F upgrades:

To use Youtube, please give your consent to the creation of cookies used by this service.

DOMINIKUS-RINGEISEN-WERK (DRW)

“We have been relying on Jenbacher Type 3 engines since 2000. Based on the positive experience with the upgrade of the first engine to the new 3F generation model in 2020, it was an easy decision for us to implement the upgrade with the second and the third engine because they always operate reliably. Thanks to the improved fuel usage of the modern 3F generation engine, we have been able to do both — increase our profitability and reduce our environmental footprint.”

Thomas Roth, head of power and engineering

Dominikus-Ringeisen-Werk (church foundation under public law).

Installed units: 3 x J312 F05

Electrical power: 3 x 551 kW

Thermal output: 3 x 695 kW

Fuel: Natural Gas

SOREMA

“Our home textile company SOREMA, established in 1976, has reaffirmed our confidence in Jenbacher by replacing a J312 D05 container with this new generation J316 F02. We are continuing with the same type of maintenance contract coverage, but this time the main maintenance intervals were favorably extended to 40/80,000 operating hours. We improved our electrical efficiency from 40.8% to 41.6% with this new 3F version, and at the same time the NOX emissions were reduced by 50% to comply with the latest emissions requirements. The recoverable thermal power increased by 83 kW, improving our production of thermal energy, which is used in our dyeing process. The new version of the DIA.NE XT4 HMI remote control program is more developed, allowing better engine performance control.”

André Relvas, Director SOREMA Portugal

Installed units: 1 x J316 F02

Electrical power: : 780 kW

Thermal output: 456 kW

Fuel: Natural Gas

Electrical Efficiency: 41,6%

AIZ STRASS IM ZILLERTAL

“After more than 80,00 operating hours with the existing Jenbacher Type 3 engine, we made the clear decision to again rely on Type 3 technology with the next generation 3F as the replacement. The exchange was simple and smooth. Right from the start, the J312F delivered both power and heat with the same reliability as before, but with a clearly noticeable increase in efficiency. As a result, more power and heat can be made available for internal processes from the volume of gas produced. The new module thus plays an important role in reducing operating costs and the environmental footprint of our wastewater treatment plant.”

Christian Fimml, Plant Manger, WWTP Achental-Inntal-Zillertal Strass

Installed units: 1 x J312 F25

Electrical power: 635 kW

Thermal output: 709 kW

Fuel: Sewage Gas

BGA MINDEROFFINGEN I

“For decades we have been relying on the Jenbacher Type 3 engines. Pairing its robustness and reliability with a higher efficiency, means that we can supply heat and power at lower operating costs.”

Petra Huggenberger, CEO, Bioenergie Minderoffingen

Installed units: 1 x J312 F225

Electrical power: 550 kW

Thermal output: 530 kW

Fuel: Biogas

BGA WECHINGEN

Since 2005 we have relied on the Jenbacher Type 3 engine platform. The reliability and robustness are outstanding, so we have decided to go for the 3F upgrade for an efficiency boost.”

Nexhip Balkaj, Manager biogas plant, Energie TG Wechingen GmbH

Installed units: 1 x J316 F225

Electrical power: 703 kW

Thermal output: 442 kW

Fuel: Biogas

Customer-only Resources

Get access to almost 2,000 Resources (such as Drawings, Service Technician Instructions, User Manuals, & more…) for Jenbacher Gas Engines with our dedicated Portal which includes advanced (yet easy to use!) search capabilities to find what you’re looking for.

Subscribe to our monthly Services Newsletter and additional materials to stay up-to-date with the latest Jenbacher technical news.

Type 3 Case studies

Agrotor (HND)

uses waste byproduct for power generation

Location

Installed engines

Electrical output

Total efficiency

Energy source

Commissioned

Klostermansfeld (GER)

for regional renewables

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Del Monte (PHL)

Jenbacher engines power 1 st combined heat and power plant to run on biogas in the Philippines

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

AMCO Produce (CAN)

Efficient, cost-effective CHP plant supports energy- and heat- intensive hydroponic production while delivering a reduced carbon footprint

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Permoda Plants (COL)

With heat and power for the textile industry that meets stringent local emissions requirements at high altitudes

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

K&C Valley (IND)

Combined heat and power plant harnesses sewage gas to generate greener power in India

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Agrotor (HND)

uses waste byproduct for power generation

Location

Installed engines

Electrical output

Total efficiency

Energy source

Commissioned

Klostermansfeld (GER)

for regional renewables

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Del Monte (PHL)

Jenbacher engines power 1 st combined heat and power plant to run on biogas in the Philippines

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

AMCO Produce (CAN)

Efficient, cost-effective CHP plant supports energy- and heat- intensive hydroponic production while delivering a reduced carbon footprint

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Permoda Plants (COL)

With heat and power for the textile industry that meets stringent local emissions requirements at high altitudes

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

K&C Valley (IND)

Combined heat and power plant harnesses sewage gas to generate greener power in India

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Our Services

Jenbacher Services

Bringing proven outcomes across the life cycle of your gas engines means less unplanned downtime, greater workforce efficiency, and lower operating costs. From commissioning to overhauling, our global network of qualified service experts provides the support you need, when you need it, by providing the latest technology.

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.