Wastewater Treatment

Don't waste waste water.

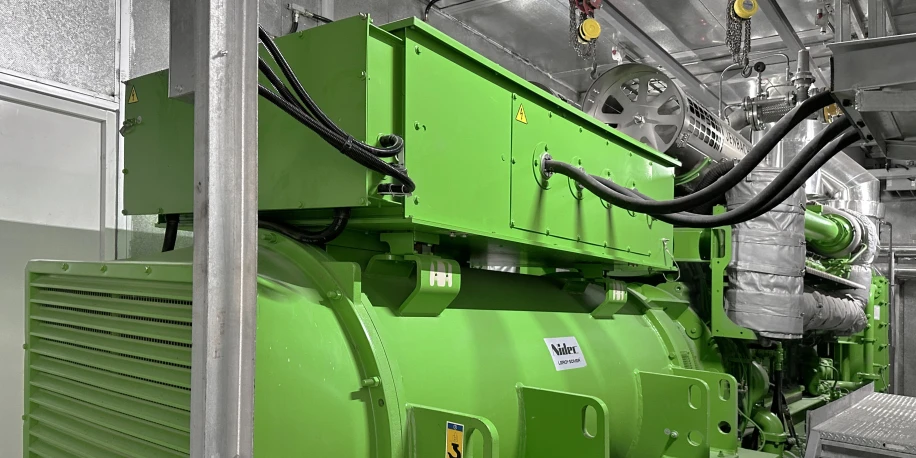

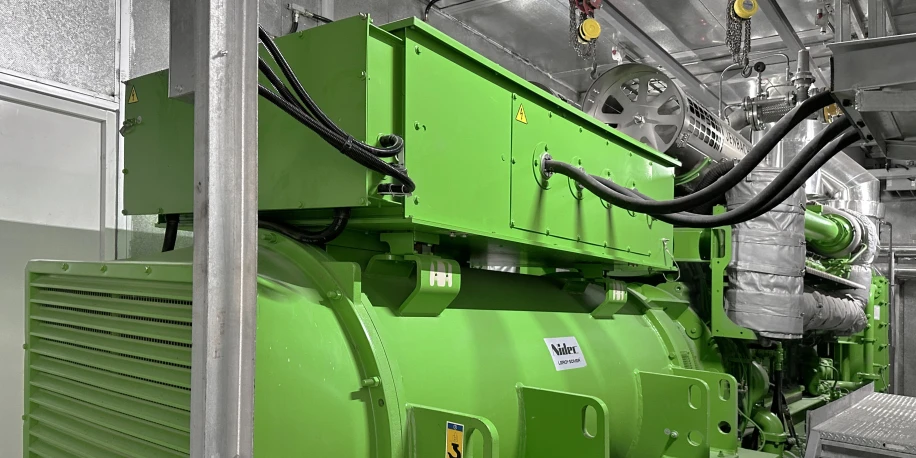

Previous generations of waste water professionals have often accepted the high costs of operating waste water treatment facilities as a consequence of meeting their discharge permit requirements. However, as the cost of energy rises and emphasis on renewable energy increases, municipalities are now seeking cost-effective and energy-efficient solutions. Jenbacher gas engines provide tailored solutions that result in long-term savings for waste water treatment plants.

Our dedicated Jenbacher experts are available to provide personal consultation.

Water treatment processes in waste water treatment plants (WWTP) include energy-intense operations, such as aeration and pumping. Second only to personnel, the leading expense to WWTP owners is the cost of energy – and these costs are on the rise. As electricity prices rise, plant operators are facing increasing energy costs in order to meet discharge permit requirements.

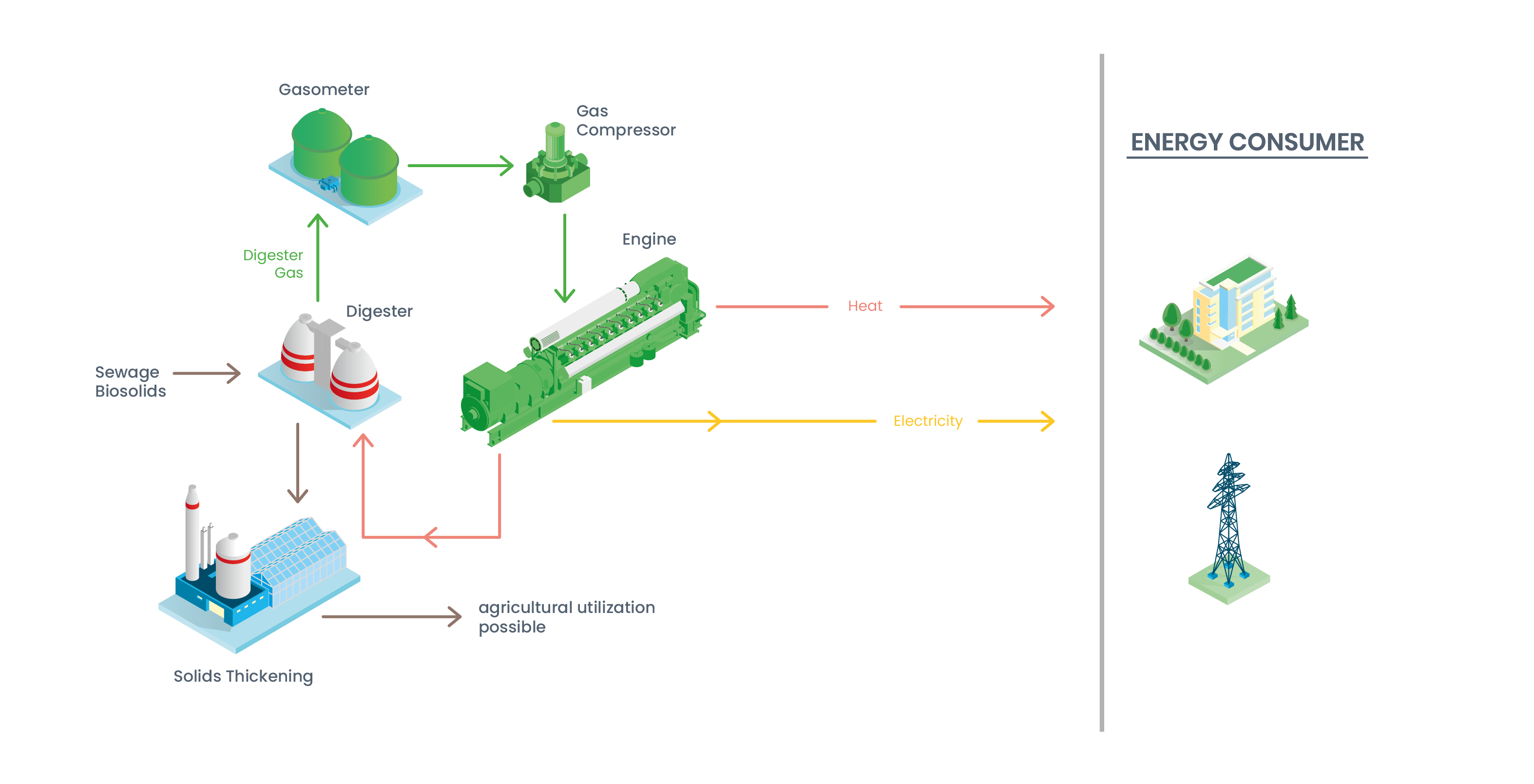

Jenbacher provides a solution for rising operating costs. In plants that employ anaerobic digestion for biosolids treatment the sewage gas that is produced can be used to produce electricity. Using modern gas engines, this renewable energy source can efficiently and reliably be converted into electricity. This can cover up to 80% (100%) of a plant’s electricity needs and eliminate the need to use fossil fuels to heat the plant.

Gas produced in anaerobic digesters from municipal WWTPs generally contains 55% to 65% methane and has a typical heating value of 6 kWh/Nm3. As a general rule, approximately 1 MW of electricity can be generated from the biosolids of waste water treated from approximately 500,000 population equivalents.

The Jenbacher concept

Jenbacher gas engines high electrical efficiencies provide renewable energy solutions and are robustly designed to handle the variable nature of sewage gas. Our extensive portfolio of engine sizes and outputs allow project designers and operators to properly match fuel availability with the engine ensuring maximum energy production, long-term reliability and the highest possible budget savings.

Selected Case Studies

El Gabar Al Asfar Wastewater Treatment Plant (EGY)

boosts power and cuts costs at one of Egypt’s largest wastewater treatment facilities

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

CN Paper Mill (CHN)

Solution reduces costs while converting waste to energy

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Concord Adela (MYS)

Award-winning plant supports the country's net-zero emissions efforts

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

K&C Valley (IND)

Combined heat and power plant harnesses sewage gas to generate greener power in India

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Wangdee Biogas Power Plant (THA)

Biogas plant delivers 4.27 MW of costeffective power while also solving the facility’s waste management issues

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

Muddy Creek Wastewater Treatment Plant (USA)

helps wastewater treatment plant increase efficiency, reduce power costs, meet environmental compliance

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

El Gabar Al Asfar Wastewater Treatment Plant (EGY)

boosts power and cuts costs at one of Egypt’s largest wastewater treatment facilities

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

CN Paper Mill (CHN)

Solution reduces costs while converting waste to energy

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Concord Adela (MYS)

Award-winning plant supports the country's net-zero emissions efforts

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

K&C Valley (IND)

Combined heat and power plant harnesses sewage gas to generate greener power in India

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Wangdee Biogas Power Plant (THA)

Biogas plant delivers 4.27 MW of costeffective power while also solving the facility’s waste management issues

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

Muddy Creek Wastewater Treatment Plant (USA)

helps wastewater treatment plant increase efficiency, reduce power costs, meet environmental compliance

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Our experts are ready to help you!

Looking for onsite power solutions?

Need access to electricity? We’re there for you.

Want to lower your energy costs, or even sell electricity back to your local grid?

INNIO’s regional experts can help you figure out the Jenbacher solution that best meets your needs. With a free consultation, you can:

- Explore the advantages of onsite power generation solutions for your company

- Discover how to use economic modeling for added financial benefit

- Get answers on the technical aspects of your project—including fuel types, feasibility studies, and equipment and balance of plant selection

- Learn how to take advantage of regional incentive programs

- Review the delivery options for your project: purchasing, financing, leasing, and engaging a service provider, such as ESCO or BOO

- Find out how to meet emissions targets

Fill out the following contact form or send us an email to contact.en@innio.com. Let’s get started!

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.