Agriculture & food processing

Keep up the pace using organic waste.

Efficiently create heat and power as a reliable alternative energy source using biogas from the fermentation of organic waste in agriculture, food and beverage production, and other industries.

Our dedicated Jenbacher experts are available to provide personal consultation.

Benefits of agricultural biogas power solutions

Across agriculture, food and beverage production, and related industries, organic waste presents both a challenge and an opportunity. Through fermentation, this waste can be converted into biogas, providing a dependable alternative energy source for on-site combined heat and power (CHP) generation. With Jenbacher engines from INNIO Group, businesses can transform organic byproducts into valuable power and heat, supporting operational efficiency and helping to reduce greenhouse gas emissions compared to conventional energy sources.

The Jenbacher solution

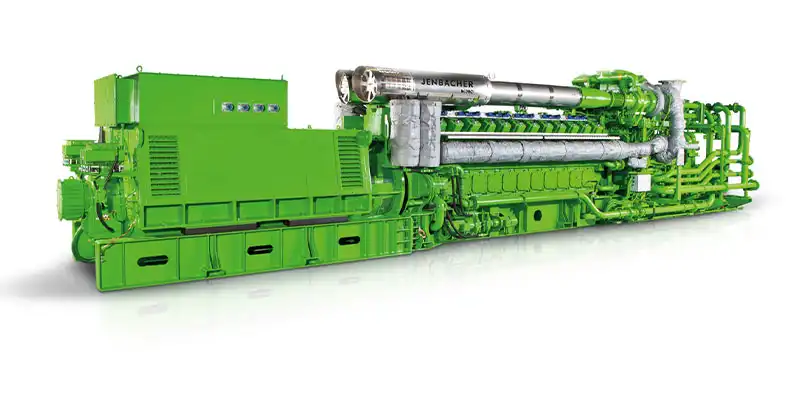

INNIO’s portfolio of Jenbacher biogas-fueled CHP systems is designed to address a wide range of operational requirements. With electrical outputs from 250 kW to 3,360 kW per unit, these systems can be scaled and combined to meet the demands of facilities of various sizes. Flexible operating modes allow plants to adapt to changing energy needs and market conditions, while the remaining substrate from biogas production can be repurposed as nutrient-rich fertilizer, supporting circular economy practices.

Real-world applications

This approach delivers results. For example, Del Monte Philippines Inc. has adopted Jenbacher CHP technology to convert pineapple processing wastewater into biogas. The energy that is created powers the company’s fruit cannery, enabling independent operation from the grid while meeting the plant’s electricity and heat needs. With two Jenbacher J420 engines and one J320 engine, Del Monte achieves up to 3.88 MW of electrical output and 3.19 MW of thermal output, reaching total system efficiencies of up to 85%. This integrated solution not only helps lower energy costs but also reduces the need for biowaste disposal.

The versatility of Jenbacher technology extends beyond biogas. Wood gas applications offer another pathway for decarbonization and energy transition. At the Bioenergie Frauenfeld plant in Switzerland, regional waste wood is converted into wood gas for Jenbacher engines, which supply electricity to approximately 8,000 households and heat to a local sugar factory. Reference installations demonstrate total efficiencies up to 95%, highlighting the reliability and effectiveness of Jenbacher solutions in diverse energy contexts.

Digital support with myplant

To further enhance performance and asset management, INNIO’s myplant digital platform provides remote support and real-time engine monitoring. With the myplant solution, businesses can improve planning, enhance engine management, and increase asset availability, contributing to longer equipment life and greater runtime.

By integrating biogas and wood gas solutions with advanced digital monitoring, businesses in agriculture and food processing can turn waste into a resource, achieve efficient on-site energy generation, and support their sustainability goals.

Key benefits

- Efficient on-site combined heat and power generation

- Use of organic waste and wood biomass as alternative energy sources

- Use of remaining substrate as nutrient-rich fertilizer

- Potential reduction in greenhouse gas emissions compared to conventional energy sources

- Avoidance of biowaste disposal costs

- Increased resilience during grid outages through island mode operation

- Scalable solutions for various facility sizes and needs

Cogeneration with Biogas

Instead of producing waste that creates emissions, organic waste — also called biomass — can be used as a valuable energy source when turned into biogas.

Selected Case Studies

Agrotor (HND)

uses waste byproduct for power generation

Location

Installed engines

Electrical output

Total efficiency

Energy source

Commissioned

Biotown (USA)

to power and heat from RNG/biomethane

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Del Monte (PHL)

Jenbacher engines power 1 st combined heat and power plant to run on biogas in the Philippines

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Concord Adela (MYS)

Award-winning plant supports the country's net-zero emissions efforts

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

Milchwerke Oberfranken (GER)

for the dairy sector

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Wangdee Biogas Power Plant (THA)

Biogas plant delivers 4.27 MW of costeffective power while also solving the facility’s waste management issues

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

Agrotor (HND)

uses waste byproduct for power generation

Location

Installed engines

Electrical output

Total efficiency

Energy source

Commissioned

Biotown (USA)

to power and heat from RNG/biomethane

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Del Monte (PHL)

Jenbacher engines power 1 st combined heat and power plant to run on biogas in the Philippines

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Concord Adela (MYS)

Award-winning plant supports the country's net-zero emissions efforts

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

Milchwerke Oberfranken (GER)

for the dairy sector

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Wangdee Biogas Power Plant (THA)

Biogas plant delivers 4.27 MW of costeffective power while also solving the facility’s waste management issues

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

Our experts are ready to help you!

Looking for onsite power solutions?

Need access to electricity? We’re there for you.

Want to lower your energy costs, or even sell electricity back to your local grid?

INNIO’s regional experts can help you figure out the Jenbacher solution that best meets your needs. With a free consultation, you can:

- Explore the advantages of onsite power generation solutions for your company

- Discover how to use economic modeling for added financial benefit

- Get answers on the technical aspects of your project—including fuel types, feasibility studies, and equipment and balance of plant selection

- Learn how to take advantage of regional incentive programs

- Review the delivery options for your project: purchasing, financing, leasing, and engaging a service provider, such as ESCO or BOO

- Find out how to meet emissions targets

Fill out the following contact form or send us an email to contact.en@innio.com. Let’s get started!

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.