Type 3, 4 and 6 Advanced Monitoring

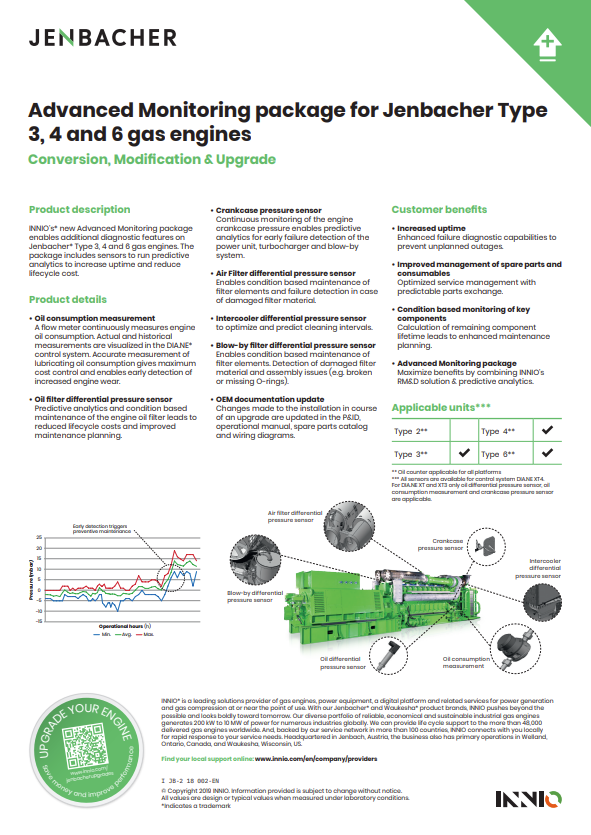

INNIO Group’s new advanced monitoring package enables additional diagnostic features on Jenbacher Type 3, 4, and 6 engines. Increase uptime and reduce life-cycle costs with sensors that run

predictive analytics.

Upgrade for:

What can this upgrade do for you?

- Increased uptime.

Enhanced failure diagnostic capabilities to prevent unplanned outages - Improved management of spare parts and consumables.

Optimized service management with predictable parts exchange - Condition-based monitoring of key components

Calculation of remaining component lifetime leading to enhanced maintenance planning - More benefits with digital package

Increase your benefits by adding INNIO Groupʼs digital myplant technology

How we get you there?

- Oil consumption measurement

A flow meter continuously measures engine oil consumption. Actual and historical measurements are visualized in the DIA.NE control system. Accurate measurement of lubricating oil consumption helps you control costs and enables early detection of increased engine wear. - Oil filter differential pressure sensor

Predictive analytics and condition-based maintenance of the engine oil filter lead to reduced life-cycle costs and improved maintenance planning. - Oil quality sensor1

Continuous oil quality monitoring combined with extended oil sampling intervals reduces the quantity of oil samples by up to one-third. This feature requires myplant Care as a minimum requirement. - Crankcase pressure sensor

Continuous monitoring of the engine crankcase pressure enables predictive analytics for early failure detection of the power unit, turbocharger, and blow-by system. - Air filter differential pressure sensor

This sensor enables condition-based maintenance of filter elements and failure detection if filter material is damaged. - Intercooler differential pressure sensor

Cleaning intervals are optimized and predicted. - Blow-by filter differential pressure sensor

Condition-based maintenance of filter elements is enabled. Damaged filter material and assembly issues (e.g., broken or missing O-rings) are detected. - OEM documentation update

Changes made to the installation resulting from an upgrade are updated in the P&ID, operational manual, spare parts catalog, and wiring diagrams.

Applicability

Applicable units 2

| Type 2 | Type 4 ✔ |

| Type 3 ✔ | Type 61✔ |

Why Jenbacher Services?

Enhanced Efficiency and Lower Lifecycle Costs

Bringing proven outcomes across the life cycle of your engines means greater engine efficiency, reduced fuel usage and optimized maintenance intervals via our Conversions, Modifications & Upgrades offerings.

Lower emission

Emissions can be reduced with exhaust gas aftertreatment systems for example, oxidation or SCR catalysts, helping to meet emission regulations.

Flexibility

Best combined with your next service event or overhaul, our upgrades use only certified OEM parts for and are always based on your specific applications.

Controls and Asset Performance Management

Manage, monitor and control your engine. Our Controls simplify proactive maintenance planning and with myplant, you can remotely calculate plant performance every day, with real-time intelligence.

ENERGY SOLUTIONS. EVERYWHERE, EVERY TIME.

Your local power generation experts.

Jenbacher gas engines have been delivered in 100-plus countries.

Resources & Downloads

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether you are looking to address your basic service needs – from maintenance requests to day-to-day spare part and consumable requirements – to technical training for your workforce, digital solutions, or even system development plans, our Jenbacher Services experts can advise you on the solution that will be right for you.

1 For Type 6 engines in combination with oils from INNIO Group

2 All sensors are available for control system DIA.NE XT 4.4 or higher. For DIA.NE XT, XT3 and XT4 to 4.3 only oil differential pressure sensor, oil consumption measurement and crankcase pressure sensor are applicable