Type 6 Lifetime Extension

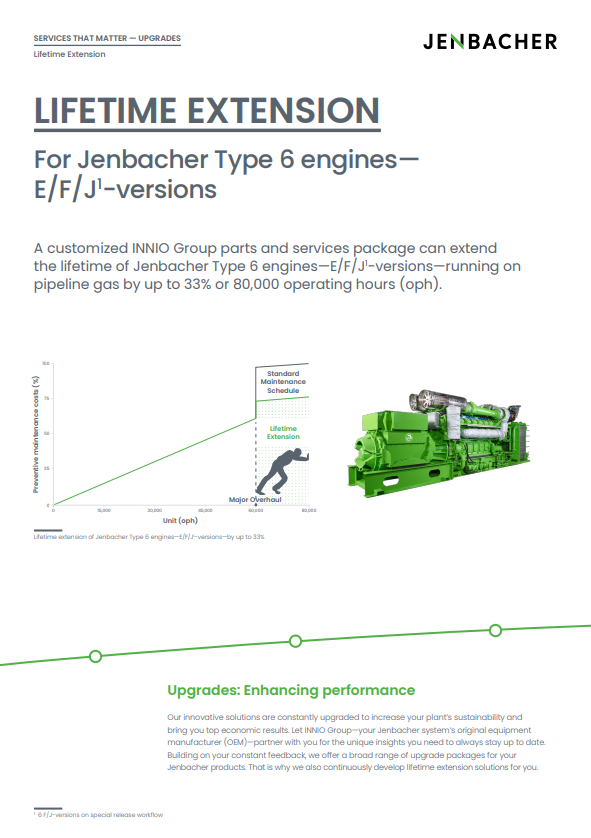

A customized INNIO Group parts and services package can extend the lifetime of Jenbacher Type 6 engines—E/F/J1-versions—running on pipeline gas by up to 33% or 80,000 operating hours (oph).

Upgrade for:

What can this upgrade do for you?

- Enhanced flexibility Allows customers to react flexibly in response to changing gas prices, feed-in tariffs, and emission regulations.

- Prolonged engine lifetime Prolongs the life of Jenbacher Type 6 engines—E/F/J2-versions—by up to 33%. With more than 57,000 engines delivered in more than 100 countries, INNIO Group has well-proven global technology experience that makes this possible.

- Service agreements option Includes a special maintenance agreement offering that covers the lifetime extension period.

How we get you there?

The lifetime extension package applied at 60,000 oph and executed on site includes:

— Mandatory upfront inspection including basic analytics performed by an authorized technical expert

— Lifetime extension core overhaul package of predefined core parts (e.g., pistons, conrod bearings, vibration damper) and on-site services

— Optional parts and services package(s) if recommended after upfront inspection and analytics

— Optional follow-up inspections and continuous analytics to monitor engine condition

— OEM documentation update

— Program conditions:

> Engine operated on pipeline gas in accordance with INNIO Group’s fuel gas specification TI 1000-0300

> Upfront inspection confirms engine suitability for an on-site repair

> Standard warranty on replaced parts and services

> Package cannot be combined with output and efficiency upgrade programs

> Does not include inspection or overhaul of auxiliaries or other equipment beyond genset scope

> Expected downtime for the lifetime extension overhaul is seven to 10 working days

Applicability

Applicable units 3

| Type 2 | Type 4 |

| Type 3 | Type 64✔ |

Why Jenbacher Services?

Enhanced Efficiency and Lower Lifecycle Costs

Bringing proven outcomes across the life cycle of your engines means greater engine efficiency, reduced fuel usage and optimized maintenance intervals via our Conversions, Modifications & Upgrades offerings.

Lower emission

Emissions can be reduced with exhaust gas aftertreatment systems for example, oxidation or SCR catalysts, helping to meet emission regulations.

Flexibility

Best combined with your next service event or overhaul, our upgrades use only certified OEM parts for and are always based on your specific applications.

Controls and Asset Performance Management

Manage, monitor and control your engine. Our Controls simplify proactive maintenance planning and with myplant, you can remotely calculate plant performance every day, with real-time intelligence.

ENERGY SOLUTIONS. EVERYWHERE, EVERY TIME.

Your local power generation experts.

Jenbacher gas engines have been delivered in 100-plus countries.

Resources & Downloads

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether you are looking to address your basic service needs – from maintenance requests to day-to-day spare part and consumable requirements – to technical training for your workforce, digital solutions, or even system development plans, our Jenbacher Services experts can advise you on the solution that will be right for you.

1 6 F/J-versions on special release workflow

3 For 60 hz applications own site-specific gearbox check required.

4 Product is applicable to all Jenbacher Type 6 engines running on pipeline gas—6 F/J version on special release workflow