Maintenance

Services that matter

Reliable expertise: In today’s dynamic environment, your energy systems must operate at high performance and efficiency levels while complying with all regulations. With our strong global network of experienced Jenbacher Services technicians, including our technical remote support team covering more than 100 countries, INNIO Group – your Jenbacher system’s original equipment manufacturer (OEM) – partners with you to provide the maintenance services you need, when you need them.

Interested? We’ll connect with you. For optimal performance, Jenbacher Services has your power plant covered.

Why the OEM?

We make a difference

Your OEM maintenance advantages

Reliable and premium service through original tools and exceptional quality standards

24/7/365 contact center availability to support your needs

Immediate support with digital remote access for data-based insights

Cost and worktime efficiency from our combination of experts, full-scope maintenance portfolio, and original parts and tools

Our portfolio

Solutions that meet your individual needs

Field Services: 1,200+ experts globally

With their deep technical knowledge about all Jenbacher engine models, our Field Services network can anticipate and perform the needed steps to help keep your energy system running at optimal availability and reliability throughout its lifespan. Plus, the team is continuously learning to support the growing complexity of your power plant operations.

Technical Support: > 50%1 of Jenbacher cases solved remotely

Our highly experienced and qualified Technical Support experts are available around the globe. Covering multiple languages, they are ready when you need them on site or remotely via our 24/7/365 contact centers. Plus, they are aided by the data and analysis from our myPlant Performance software.

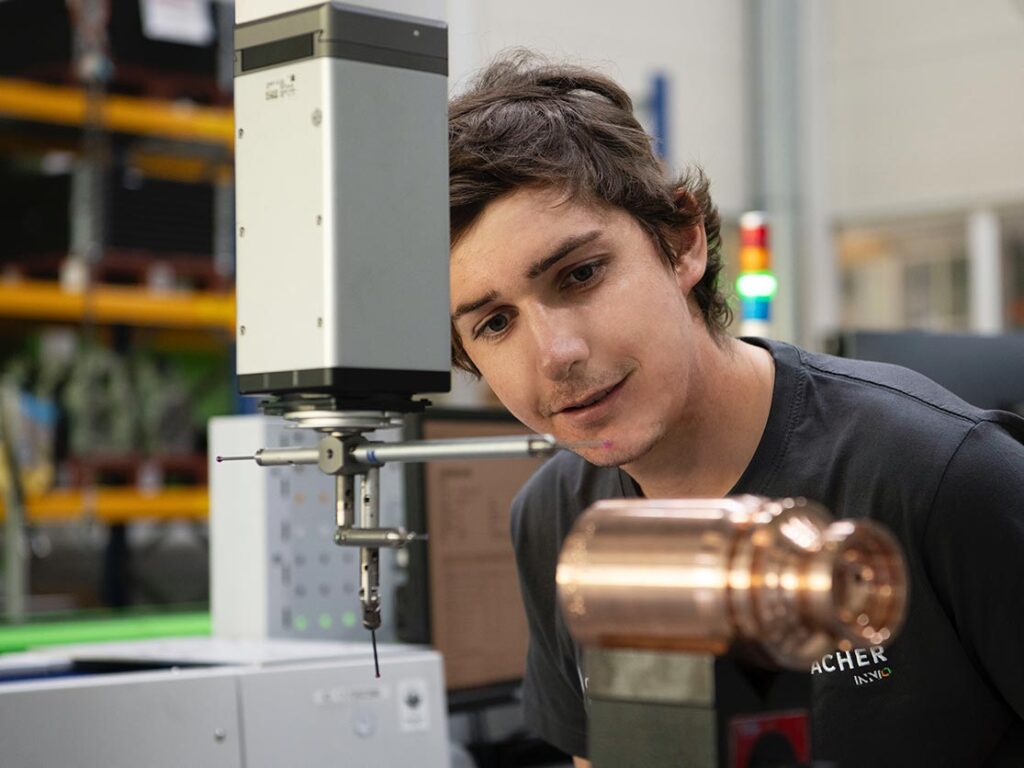

OEM tooling: the best fit

Having the right tools in place can make the difference. Designed for various applications, and based on high-quality standards, our Jenbacher OEM tools perfectly harmonize with our engine specifications and display outstanding performance in field trials.

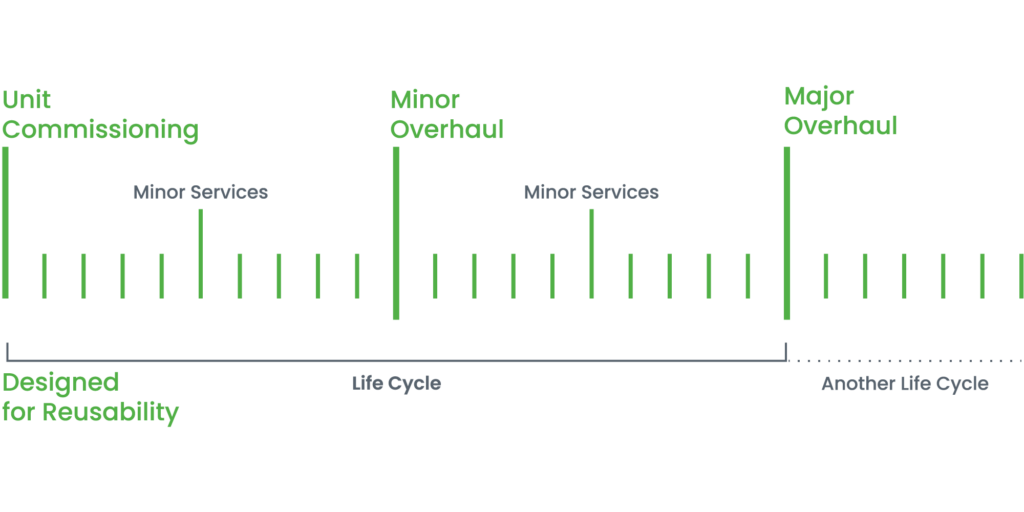

OEM maintenance: a circular approach

Staying within our recommended maintenance schedule allows you to opt for an additional life cycle when your equipment comes to the end of its original life. Our wide-ranging portfolio of Remanufacturing solutions and reUp products offers you a circular way to optimize resources and materials.

OEM expert maintenance for your Jenbacher plant's lifespan

The economic value you gain

Jenbacher maintenance pays off

1,200+

Certified Jenbacher and authorized distributor field technicians

24/7/365

Technical Support accessibility

> 50%1

Remote fix rate, meeting your operational needs through remote maintenance

Case Studies

Maintaining reliability even during expansion

“INNIO Group is the right partner for us. We are impressed by their deep OEM knowledge and happy about their continued project support. We experienced this during our plant expansion to provide heat supply. The proposed modification from Jenbacher Technical Support was implemented within a short timeframe during which our plant was able to continue generating electricity. With the modification, the system has been working completely reliably according to our requirements, and all original fluctuations in heat consumption production have been solved by the upgraded system. Thank you!”

Milan Kajtman, Co-owner of Smart BioEnergy s.r.o., Biogas Plant in Písek, Czech Republic

Immediate support with remote monitoring

"Thanks to INNIO Group’s remote monitoring, which is based on its myPlant Performance digital platform, we immediately know about any deviations in our engines’ performance. With real-time data connection, the Jenbacher Services experts help us keep our engines up and running by quickly analyzing our plant data, and then advising and interacting when needed. This immediate response capability is of utmost importance to us in support of our self-sufficient island mode approach and our highly sensitive dairy production methods."

Daniel Estrada, Plant Operations Manager, Biotek Power S.A. de C.V., Island mode operation in Mexico

Maintaining reliability even during expansion

“INNIO Group is the right partner for us. We are impressed by their deep OEM knowledge and happy about their continued project support. We experienced this during our plant expansion to provide heat supply. The proposed modification from Jenbacher Technical Support was implemented within a short timeframe during which our plant was able to continue generating electricity. With the modification, the system has been working completely reliably according to our requirements, and all original fluctuations in heat consumption production have been solved by the upgraded system. Thank you!”

Milan Kajtman, Co-owner of Smart BioEnergy s.r.o., Biogas Plant in Písek, Czech Republic

Immediate support with remote monitoring

"Thanks to INNIO Group’s remote monitoring, which is based on its myPlant Performance digital platform, we immediately know about any deviations in our engines’ performance. With real-time data connection, the Jenbacher Services experts help us keep our engines up and running by quickly analyzing our plant data, and then advising and interacting when needed. This immediate response capability is of utmost importance to us in support of our self-sufficient island mode approach and our highly sensitive dairy production methods."

Daniel Estrada, Plant Operations Manager, Biotek Power S.A. de C.V., Island mode operation in Mexico

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether you are looking to address your basic service needs – from maintenance requests to day-to-day spare part and consumable requirements – to technical training for your workforce, digital solutions, or even system development plans, our Jenbacher Services experts can advise you on the solution that will be right for you.

1The number refers to connected Jenbacher engines.