Upgrades

Services that matter

Enhancing performance: The continuous adjustments we make with our innovative solutions can increase your plant’s sustainability and bring you top economic results. Let INNIO Group – your Jenbacher system’s original equipment manufacturer (OEM) – partner with you for the unique insights you need to always stay up to date. INNIO Group knows how to support you proactively so you can continuously improve to meet your ambitious efficiency and climate goals. After all, we have delivered about 1,000 upgrades annually over the past 10-plus years!

Interested? We’ll connect with you. For optimal performance, Jenbacher Services has your power plant covered.

Why the OEM?

Supporting upgrades that matter

Your OEM upgrade advantages

In-house testing and validation, matching to the DNA of our engine

After Sales Support, with technicians trained on our upgrades

Our portfolio

Jenbacher upgrade packages make a difference

Increase efficiency

Lower your life-cycle costs through higher engine efficiency and reduced fuel consumption.

Increase power

Obtain a boost in nominal power output over the life of your unit with a power output increase upgrade package.

Reduce emissions

Meet your emissions requirements with our continuously enhanced, tailored emissions control systems and analytics upgrades.

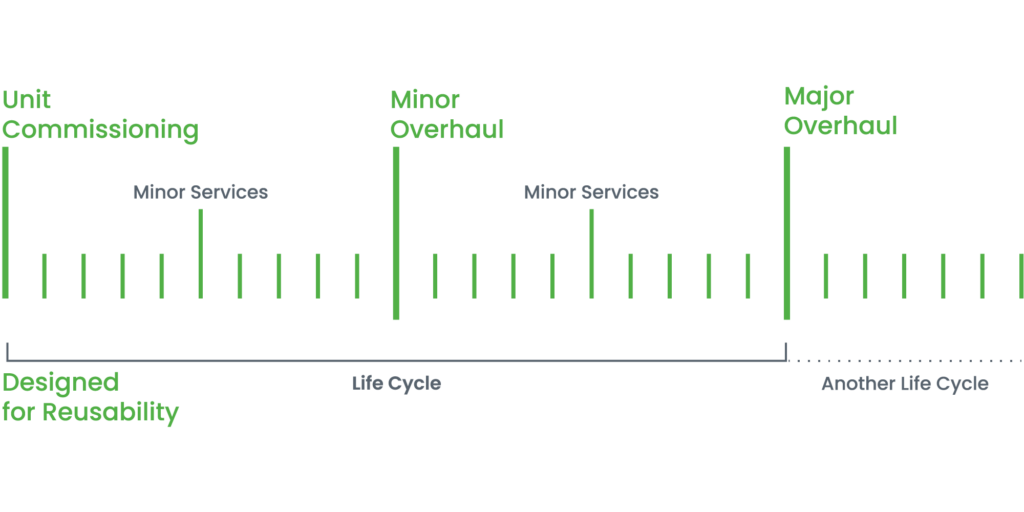

Extend lifetime

Boost your engine’s lifetime by several additional years (up to five years for peaking applications) with our lifetime extension upgrades.

Gain better control of your plant

Get significantly improved options for plant management directly on the engine or via remote monitoring. Additionally, you can opt for the latest features available from myplant Performance – our tailored digital remote support platform.

Receive future-oriented investment security

Our options for the use of CO2-neutral fuels (e.g., all new Jenbacher engines are “Ready for H2”1) support future- oriented investment security for your plant operation.

Lifetime extension

The economic value you gain

Investing in the latest technology upgrades pays off

Significant saving potential

when upgrading to the 3F version with biogas

Biogas prices can fluctuate heavily

In some cases where biogas is a byproduct, it may even be free.

Case Studies

The difference a Jenbacher upgrade package can make

"Our past experience of Jenbacher upgrades was so positive that it was an easy decision for us to upgrade to the next generation of the Jenbacher Type 3F. Thanks to the improved fuel usage of the modern 3F generation engine, we have been able to both increase our profitability and reduce our environmental footprint."

Thomas Roth, Head of Power and Engineering for Dominikus-Ringeisen-Werk (DRW), Bavaria, Germany

Successful conversion to hydrogen in Hamburg

"We have demonstrated that our Jenbacher combined heat and power plant from INNIO Group can operate reliably with 100% hydrogen."

Dr. Nikolaus Meyer, Managing director of Hansewerk Natur GmbH, Hamburg, Germany

The Jenbacher emissions reduction package for full control over your exhaust gas levels

"The Jenbacher OEM solution for emissions reduction offers engine-specific and complementary technologies from a single source. As a result, INNIO Group is helping us in our efforts to achieve a climate-neutral energy supply and at the same time making it easier for us to comply with the prescribed emission limits."

Manuel Kirfel, Development/Sales Heat, STAWAG - Stadt- und Städteregionswerke Aachen AG

The difference a Jenbacher upgrade package can make

"Our past experience of Jenbacher upgrades was so positive that it was an easy decision for us to upgrade to the next generation of the Jenbacher Type 3F. Thanks to the improved fuel usage of the modern 3F generation engine, we have been able to both increase our profitability and reduce our environmental footprint."

Thomas Roth, Head of Power and Engineering for Dominikus-Ringeisen-Werk (DRW), Bavaria, Germany

Successful conversion to hydrogen in Hamburg

"We have demonstrated that our Jenbacher combined heat and power plant from INNIO Group can operate reliably with 100% hydrogen."

Dr. Nikolaus Meyer, Managing director of Hansewerk Natur GmbH, Hamburg, Germany

The Jenbacher emissions reduction package for full control over your exhaust gas levels

"The Jenbacher OEM solution for emissions reduction offers engine-specific and complementary technologies from a single source. As a result, INNIO Group is helping us in our efforts to achieve a climate-neutral energy supply and at the same time making it easier for us to comply with the prescribed emission limits."

Manuel Kirfel, Development/Sales Heat, STAWAG - Stadt- und Städteregionswerke Aachen AG

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether you are looking to address your basic service needs – from maintenance requests to day-to-day spare part and consumable requirements – to technical training for your workforce, digital solutions, or even system development plans, our Jenbacher Services experts can advise you on the solution that will be right for you.

1 „Ready for H2“ bedeutet, dass die Jenbacher Anlage grundsätzlich in Zukunft auf den Betrieb mit bis zu 100% Wasserstoff umgerüstet werden kann. Details wie Kosten und Zeitrahmen für eine solche Umrüstung können variieren und müssen individuell geklärt werden.