Automatic Alternator Lubrication Retrofit

INNIO Group’s automatic generator lubrication system reliably lubricates your generator bearings, reducing wear and maintenance effort. Cartridge replacement intervals can be synchronized with standard maintenance schedules, while DIA.NE control system integration keeps you informed in real time. The upgrade also helps with service planning, lowering costs.

Upgrade for:

What can this upgrade do for you?

- Reduced bearing stress

Smaller, more frequent greasing events reduce the lubrication amount, lowering bearing stress. - Less risk of dirt ingress

A closed-loop system helps prevent contamination from dirt ingress during generator bearing lubrication. - Lower life-cycle costs

Cartridge exchanges align with standard maintenance tasks, reducing travel and labor time.

How we get you there?

By distributing grease in smaller, more frequent intervals, the system reduces stress on generator bearings. This comprehensive Jenbacher upgrade package includes necessary components to enhance your asset’s performance.

Typical engine upgrade scope:

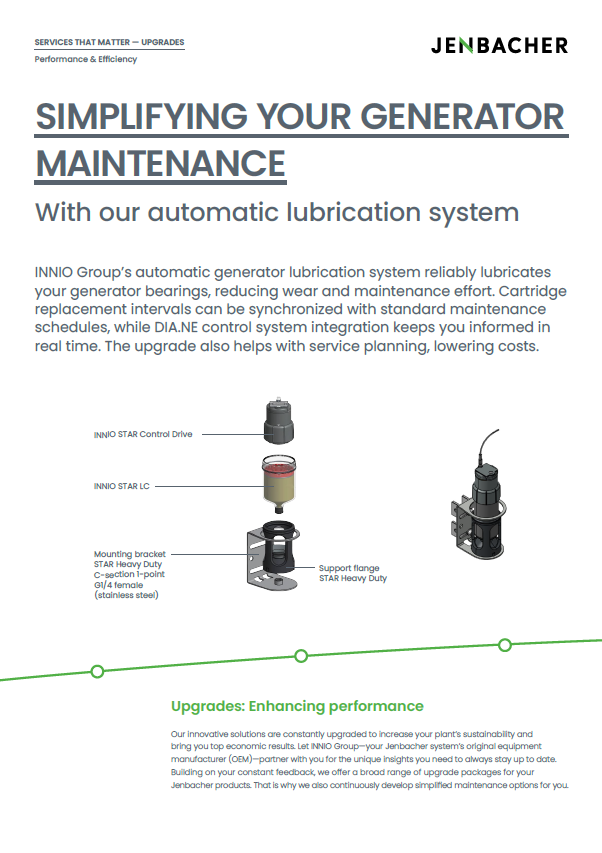

Main components:

— Drive unit

— Grease cartridge

— Hose

— Connecting cable

— Mounting bracket

— Terminal

— DI.ANE control system integration

— Installation and commissioning instructions

— Updated maintenance plan (inspection)

OEM documentation update

Installation changes resulting from the upgrade are reflected in the operational manual and spare parts catalog.

Timing

The upgrade is best implemented as soon as possible and can be integrated early in the engine’s life cycle.

Applicability

Applicable units 1

| Type 2 | Type 41✔ |

| Type 31 ✔ | Type 61✔ |

Why Jenbacher Services?

Enhanced Efficiency and Lower Lifecycle Costs

Bringing proven outcomes across the life cycle of your engines means greater engine efficiency, reduced fuel usage and optimized maintenance intervals via our Conversions, Modifications & Upgrades offerings.

Lower emission

Emissions can be reduced with exhaust gas aftertreatment systems for example, oxidation or SCR catalysts, helping to meet emission regulations.

Flexibility

Best combined with your next service event or overhaul, our upgrades use only certified OEM parts for and are always based on your specific applications.

Controls and Asset Performance Management

Manage, monitor and control your engine. Our Controls simplify proactive maintenance planning and with myplant, you can remotely calculate plant performance every day, with real-time intelligence.

ENERGY SOLUTIONS. EVERYWHERE, EVERY TIME.

Your local power generation experts.

Jenbacher gas engines have been delivered in 100-plus countries.

Resources & Downloads

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether you are looking to address your basic service needs – from maintenance requests to day-to-day spare part and consumable requirements – to technical training for your workforce, digital solutions, or even system development plans, our Jenbacher Services experts can advise you on the solution that will be right for you.

1 Das Upgrade ist für Motoren der Baureihen 3, 4 und 6 mit Generatoren vom Typ HCI634, PE734, DIG142, HVSI804 und LVSI804 verfügbar. Nur in Europa erhältlich. Erfordert DIA.NE XT4.4 oder höher, einschließlich Basis-Update.