Greenhouses

Let's talk about power plants.

Jenbacher technology is fueling life itself, in greenhouses growing food and other plants. The benefits of cogeneration for greenhouses go well beyond heating and lighting.

Our dedicated Jenbacher experts are available to provide personal consultation.

A global increase in both food demand and environmental awareness has led to a rapid rise in the greenhouse horticulture industry. That is because greenhouses today have the ability to simultaneously increase the viability of their crops and effectively control carbon dioxide (CO2) emissions. Jenbacher technology can provide you with heat, electricity and CO2 fertilization, increasing your greenhouse’s total efficiency, profitability and plant production. Today, more than 1,500 Jenbacher cogeneration units with CO2 fertilization have been installed worldwide, providing about 3,300 MW of power.

The Jenbacher solution

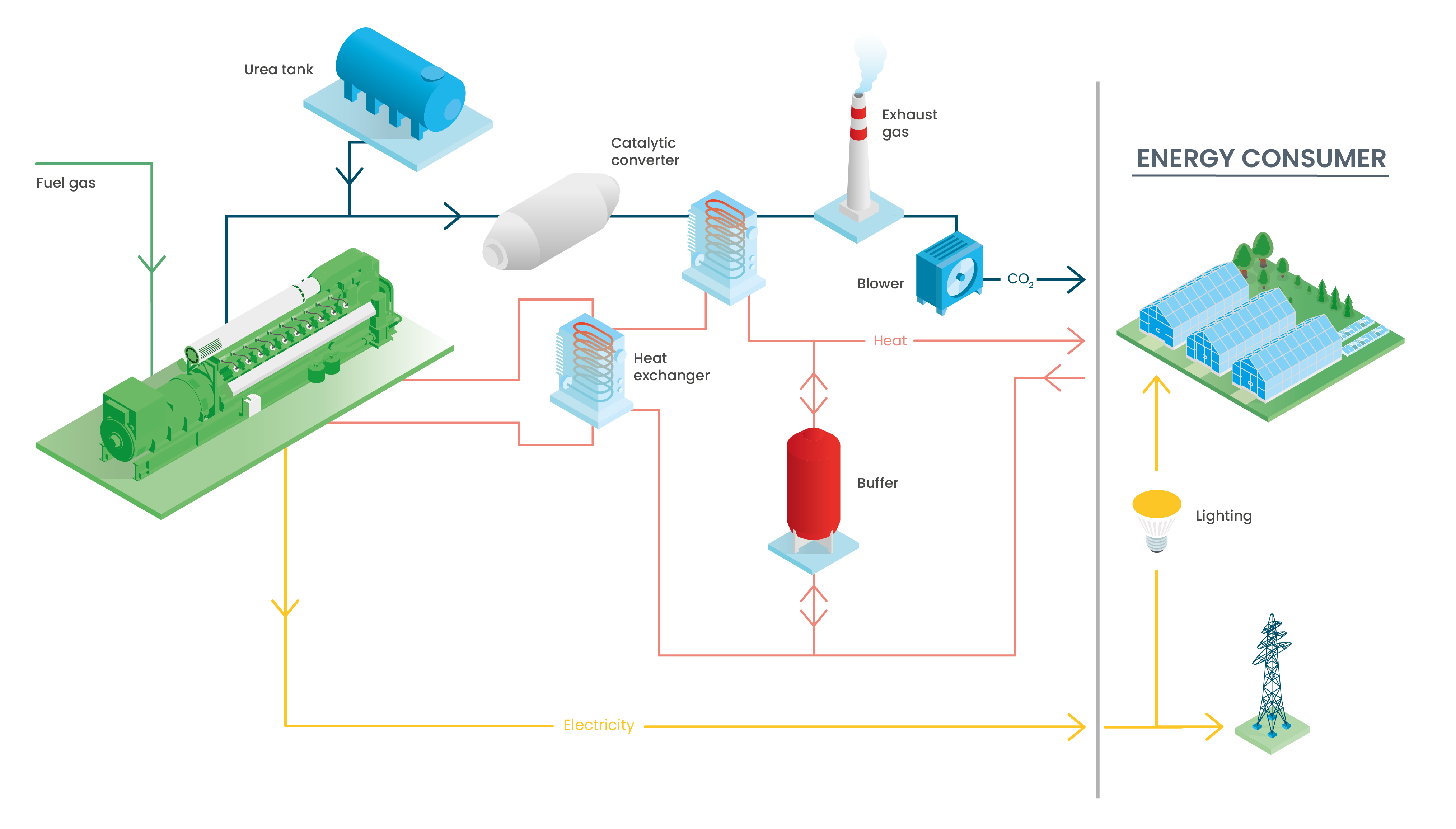

Jenbacher combined heat and power (CHP) systems not only provide electricity for on-site or public grid use, but also heat and CO2 to fertilize plants and meet the requirements of an efficient greenhouse. By increasing the intensity of the artificial lighting that is found in some greenhouses, plants absorb even more CO2. Plant growth and the subsequent harvest yield can be significantly increased by enriching the greenhouse environment with CO2, keeping the temperature constant, and providing sufficient lighting.

The energy created by gas engine cogeneration systems in greenhouses can be used in various ways. The electricity can provide the power for artificial lighting and/or be fed into the public grid. And while the heat can efficiently meet the greenhouse’s requirements, the CO2

from the engine exhaust gas can help fertilize the plants. That is because the exhaust from gas engines burning natural gas contains approximately 0.2kg of CO2 per kWh of energy input.

GREENHOUSE BROCHURE

Download our “Let’s talk about power plants” greenhouse brochure for more detailed information.

CHP benefits for Greenhouses

- Reduction of operating costs by implementing a combined heat and power system

- Containerized, ready-to-use solutions, dedicated turn-key solutions for greenhouses

- Potential to earn additional revenue supplying excess power to the public utility grid

- Possibility to capture engine exhaust CO2 and use it as high-quality plant fertilizer

- Ability to store CO2 and heat for a time-independent supply

- Minimized footprint with compact design

- Yield overall efficiency as high as 95%

Selected Case Studies

Biohof Querdel (GER)

A contribution to the energy transition in Germany

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Den Berk Délice (BEL)

with combined heat and power

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

AMCO Produce (CAN)

Efficient, cost-effective CHP plant supports energy- and heat- intensive hydroponic production while delivering a reduced carbon footprint

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

AGR Fenland Glasshouse (GBR)

CHP energy center with an innovative heat pump system delivers power and heat with 30% less CO2 than conventionally heated greenhouses

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Biohof Querdel (GER)

A contribution to the energy transition in Germany

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Den Berk Délice (BEL)

with combined heat and power

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

AMCO Produce (CAN)

Efficient, cost-effective CHP plant supports energy- and heat- intensive hydroponic production while delivering a reduced carbon footprint

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

AGR Fenland Glasshouse (GBR)

CHP energy center with an innovative heat pump system delivers power and heat with 30% less CO2 than conventionally heated greenhouses

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Our experts are ready to help you!

Looking for onsite power solutions?

Need access to electricity? We’re there for you.

Want to lower your energy costs, or even sell electricity back to your local grid?

INNIO’s regional experts can help you figure out the Jenbacher solution that best meets your needs. With a free consultation, you can:

- Explore the advantages of onsite power generation solutions for your company

- Discover how to use economic modeling for added financial benefit

- Get answers on the technical aspects of your project—including fuel types, feasibility studies, and equipment and balance of plant selection

- Learn how to take advantage of regional incentive programs

- Review the delivery options for your project: purchasing, financing, leasing, and engaging a service provider, such as ESCO or BOO

- Find out how to meet emissions targets

Fill out the following contact form or send us an email to contact.en@innio.com. Let’s get started!

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.